Silval Special Alloys Plant has been an active manufacturing facility since 2020.

As of 2025, it is fully owned by Raffmetal, the leading European producer of aluminum alloys from recycling.

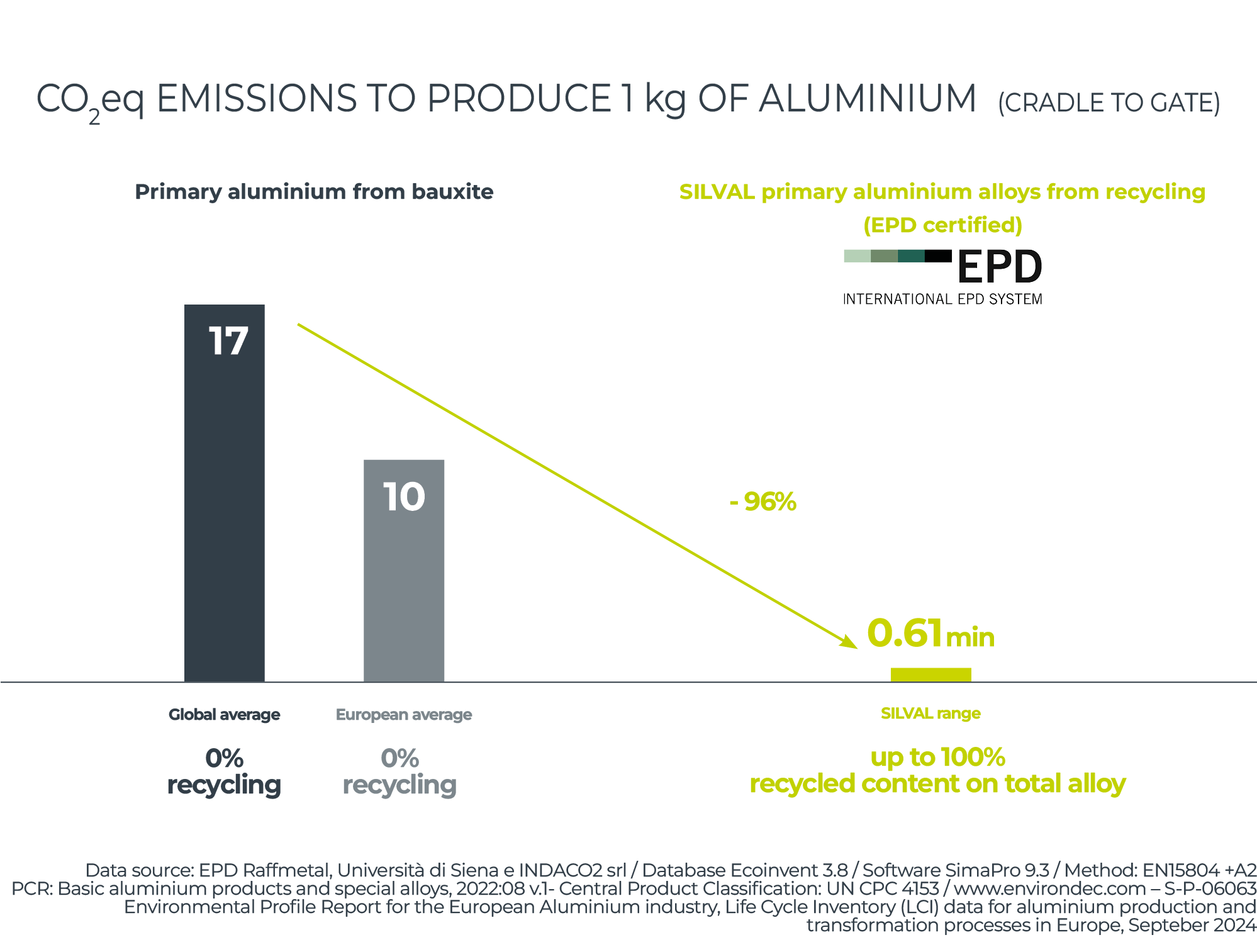

Thanks to its expertise in scrap processing and sorting systems, along with state-of-the-art facilities, it stands out as a unique producer of primary aluminum alloys from recycling, capable of offering high-quality products with a low Carbon Footprint.